our process

100% ORGANIC COTTON

CALIFORNIA GROWN

our 100% Organic Cotton

Our 100% Organic cotton is cultivated in California then cut and manufactured in Los Angeles. This makes our tees made in USA from start to finish. By using local resources, it not only helps reduce impact in our environment by leaving less carbon footprint in the transport process, but also shows off the quality of California cotton! We proudly say "100% Organic" because it also goes through a vegetable dye process that is free of harmful toxins.

Our organic Cotton Tee feels light-weight, Super soft and has a small neck binding. It is comfortable year round and washes beautifully. Never underestimate the quality and beauty of California cotton!

Details:

100% G.O.T.S. certified GMO free organic cotton

dyed in G.O.T.S certified organic dye process (low impact, less water, no metals and chemicals ingredients)

all process made in beautiful California!

GARMENT DYE

TOXIN FREE

Muscatti Vegetable Dye Process

We proudly say "100% Organic" because our California grown cotton goes through our vegetable dye process. We are one of the only companies that do 100% Organic vegetable dyes in Los Angeles California and we are very proud of that. Organic materials aren't treated with pesticides, insecticides, herbicides and Genetically Modified Organisms. These toxins are harmful for farmers and workers, us as consumers, and entire wildlife eco-systems.

Details:

dyed in G.O.T.S certified organic dye process (low impact, less water, no metals and chemicals ingredients)

all shirts are individually garment dyed and softened for a comfortable feel.

all process made in beautiful California!

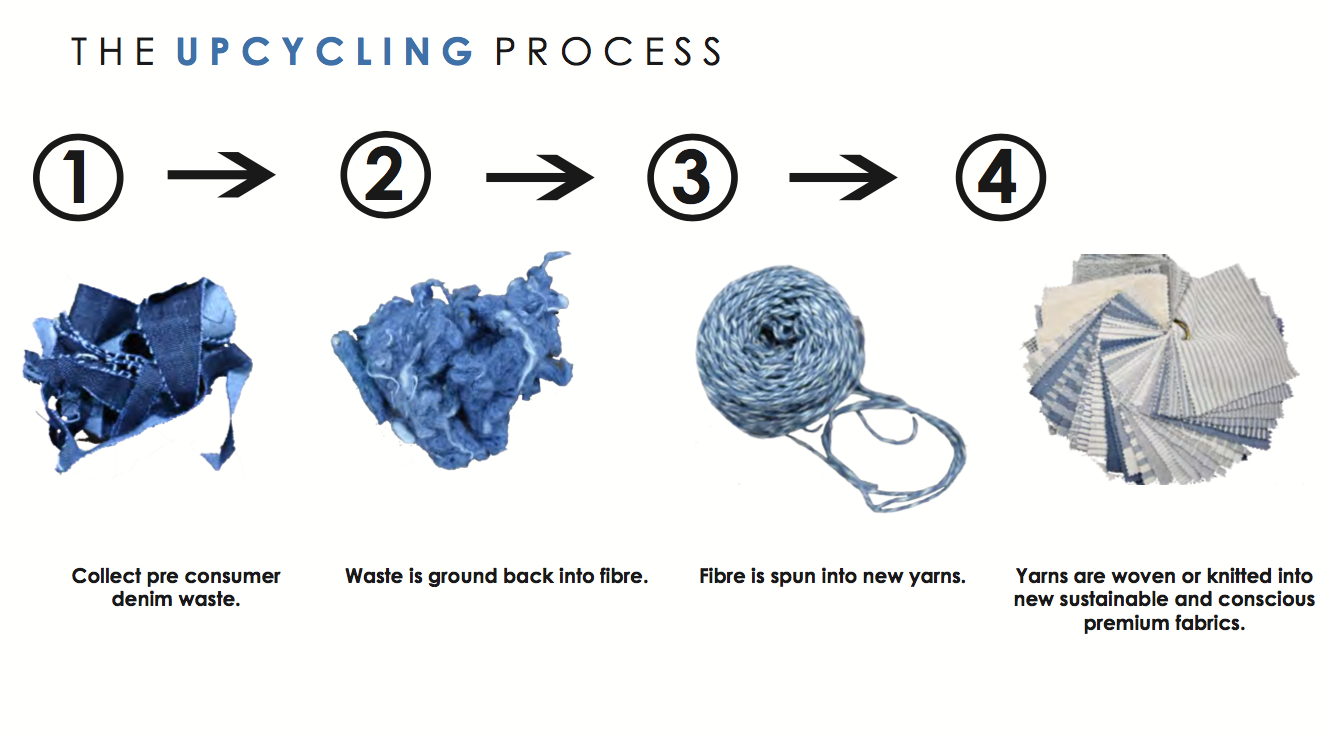

THE UPCYCLING PROCESS

We love to use fabrics that have gone through an upicycle process. This means that all fabrics and yarns are eco-friendly and made of 100% upcycled pre-consumer denim waste. The manufacturing process is chemical free, dye free, and uses minimal water energy. This process takes discarded fabrics and spins them into new yarns to create new amazing fabrics! There is also ZERO waste through this process because whatever can no longer be spun or is left over in the upcycling process is then donated to farmers and coffee growers because they use as compost and natural fertilizer for their soil. It is important to do our part in keeping a natural balance in our planet.

Details:

Blue tint is from old blue denim and white tint is from discarded cotton

G.O.T.S certified organic process (low impact, less water, no metals and chemicals ingredients)

Saves over 5000 gallons of water for every 1kg of upcycled material

DENIM TREATMENT

WATERLESS

OZONE DENIM TREATMENT

Ozone denim process uses the natural bleaching capabilities of ozone gas to give specialty bleach effects while reducing our environmental impact. Ozone can be used to clean pocket backstaining from normal washing processes, or to bleach denim to a lighter shade. The use of Ozone treatment is like bleaching, but it eliminates the use of actual chemical bleaching when creating lighter shades of denim. The system is much faster than traditional processes which helps reduce amount of energy used. Ozone systems are waterless, but in the certain parts of our process we end up using a little water. We do not eliminate the complete use of water, but it is a huge difference in the amount we save overall. 900 million people lack water in many parts of the world and we need to stop contaminating our water and taking it for granted.

Details:

No chemical bleaching

Less water, less energy

Ozone treatment saves 20-60 liters of water per pair of jeans